What is a Digital Plate-less Printer ? Technological Innovation Leading the Future of the Printing Industry

- 28 2 月, 2025

- FERONIAYANG

- 11:44 上午

In today’s fast-paced business environment, efficiency and flexibility are key to corporate success. Whether it’s packaging, advertising, or personalized customization, traditional printing methods often fail to meet the demands of the modern market. Issues such as long plate-making times, high costs, and poor flexibility have troubled many businesses. The advent of the Digital Plate-less Printer has completely transformed this scenario.

If you are searching for a printing solution that can reduce costs, enhance efficiency, and also be environmentally friendly, then the Digital Plate-less Printer is undoubtedly your best choice. Next, we will provide you with a detailed introduction to the working principles, main advantages, classifications, and application areas of Digital Plate-less Printers, helping you to fully understand this revolutionary technology.

Catalog

I. Definition and Working Principles of Digital Plate-less Printers

A Digital Plate-less Printer is a digital printing device that eliminates the need for traditional plate-making processes. It directly controls the print head or inkjet system through a computer, outputting electronic files (such as PDFs, images, etc.) directly onto various media surfaces, including paper, cardboard, plastic, and metal. Its core technologies include high-precision inkjet technology, digital color management, and variable data printing, enabling a “zero intermediate steps” production model from design to finished product.

Digital printing has a higher cost per page than more traditional offset printing methods, but this price is usually offset by avoiding the cost of all the technical steps required to make printing plates.Ideal for short-run jobs, this method enables cost-effective customization, quick turnaround times, and seamless variable data printing (VDP) for personalized materials, on-demand packaging, or promotional items.

Working Principles:

Digital Input: Users complete graphic design and layout using design software to generate electronic files.

Direct Output: The file is processed by the printer’s built-in RIP (Raster Image Processor), which drives the inkjet head or other printing units to precisely eject ink onto the surface of the substrate.

Instant Curing: Some models use UV ink or thermal curing technology to ensure rapid drying and strong adhesion of the printed patterns.

II. Key Advantages of Digital Plate-less Printers

Compared to traditional printing technologies, digital plate-less printers demonstrate significant advantages in efficiency, cost, and environmental sustainability:

1. No Plate-making Required, Saving Time and Costs

Technical Details:

Direct Output Technology: Digital plate-less printers use digital files (such as PDF, AI, PSD) to directly drive inkjet heads or laser imaging modules, bypassing traditional steps like plate-making, plate exposure, and machine setup.

Zero Inventory Pressure: Traditional printing requires pre-made and stored printing plates (each set costing approximately 100–100–500), while digital plate-less technology allows for on-demand use of electronic files, eliminating plate wear and storage costs.

Application Scenarios:

Urgent Order Processing: A cosmetics brand needed to produce 5,000 limited-edition gift boxes within 48 hours. The digital plate-less printer directly output the design files without waiting for plate-making, ensuring on-time delivery.

2. High Efficiency and Flexibility, Supporting On-Demand Production

Technical Details:

Variable Data Printing (VDP): Real-time adjustment of printing content through software, such as embedding unique serial numbers, QR codes, or personalized customer information on labels or invoices, enabling customized output of “10,000 different copies.”

Automated Workflow: Some high-end models integrate with ERP/MES systems to automatically receive orders and schedule production, reducing human errors.

Application Scenarios:

Personalized Marketing: A chain coffee brand used digital plate-less printers to print customer names and dynamic promotional codes on cups, enhancing user engagement.

3. High Precision and Broad Applicability

Technical Details:

Ultra-fine Printing:

Industrial-grade inkjet heads (e.g., Kyocera KJ4A) can achieve a minimum droplet size of 3pl, with resolutions up to 2400×1200 DPI, surpassing traditional offset printing in detail reproduction.

White Ink Circulation Technology: Prints a white base layer on dark media (e.g., black acrylic) before overlaying colored patterns, ensuring color saturation.

Media Compatibility:

Adjustable platforms and intelligent media detection support automatic focus printing on materials ranging from 0.1mm ultra-thin PET film to 50mm thick wooden boards.

Application Scenarios:

Complex Surface Printing: An automotive interior supplier used a six-axis robotic arm with a digital inkjet head to directly print wood-grain patterns on curved dashboard surfaces.

4. User-friendly Operation, Reducing Labor Dependency

Technical Details:

Intelligent Calibration Systems:

Automatic Nozzle Alignment: Uses cameras to scan test patterns and adjust inkjet head positions in real time, with errors controlled within ±0.1mm.

Automatic Color Matching: Built-in spectrophotometers linked to Pantone color libraries ensure consistent color across batches.

Remote Maintenance: IoT modules enable manufacturers to remotely diagnose equipment status and provide software updates, minimizing downtime.

Application Scenarios:

Unattended Production: A 24-hour printing center used digital plate-less printers to automatically receive orders and complete overnight production, with shipments ready the next day.

5. Environmental Sustainability

Technical Details:

Eco-friendly Ink Technology:

UV-LED Curable Ink: Instant curing via ultraviolet light, with no solvent emissions and near-zero VOC release.

Water-based Ink: Suitable for food-grade packaging printing, FDA-certified, and pollution-free.

Waste Control: Digital plate-less printing has a defect rate of less than 1% (compared to 5%–10% for traditional offset printing) and supports ink recycling systems (e.g., Epson’s Micro Piezo waste ink circulation module).

Application Scenarios:

Green-certified Products: An organic food brand required packaging printing to use VOC-free ink, and digital plate-less technology helped it achieve organic certification.

III. Classification and Features of Digital Plate-less Printers

Digital plate-less printers can be categorized into three main types based on their technical pathways, print head configurations, and functional integration: single-pass, multi-pass, and hybrid printers. Below is a detailed breakdown of each type, including their core technologies, model comparisons, and typical applications:

1. Single-pass Printers

The Single Pass Printer (also known as One Pass Printer) is a revolutionary digital printing solution designed for high-speed, precision, and energy-efficient industrial applications. Utilizing advanced Single Pass scanning technology, it enables full-image printing in a single scan, eliminating the need for multiple passes and significantly boosting productivity while maintaining exceptional print quality. Ideal for industries requiring rapid, large-scale printing with minimal downtime.

Technical Principles:

Single Inkjet Head Architecture: Utilizes one set of piezoelectric or thermal inkjet heads for unidirectional printing along the media’s movement direction (Y-axis), with full coverage achieved through media movement (X-axis).

Ink Types: Primarily water-based inks, with some models supporting UV-curable inks (requires additional LED light modules).

Model Comparison:

Model Type | Core Features | Resolution | Suitable Media |

Economy Desktop Printer | Lightweight design, supports A3 size | 600×600 DPI | Paper, adhesive labels |

Industrial Roll-to-Roll | High-speed continuous feed, supports roll materials | 1200×1200 DPI | Films, flexible packaging, textiles |

Corrugated Board Printer | Heavy-duty platform, prints up to 3mm thick corrugated board | 720×720 DPI | E/F flute board, gray-back cardboard |

Industry Applications:

Label Printing: Short-run orders like food labels and pharmaceutical inserts, supporting variable data (e.g., batch numbers, barcodes).

Proofing: Packaging companies use single-pass printers for quick design proofs before mass production.

2. Multi-pass Printers

The Multi Pass Printer,also known as a scanning printer, is a type of digital printing equipment that achieves high precision and superior print quality through multiple printhead scans or layered ink droplet deposition. Compared to Single Pass Printers, which complete printing in a single high-speed pass, Multi Pass Printers significantly enhance color gradient smoothness, detail reproduction, and media adaptability by using multiple paths and layers of ink deposition. This makes them particularly suitable for applications requiring extremely high image fidelity.

Technical Principles:

Multi-head Array Technology: Uses 4–8 inkjet heads arranged in parallel, supporting combinations of CMYK + white ink + varnish for multi-color layering or double-sided printing in a single pass.

Color Management: Employs closed-loop color calibration systems with built-in spectrophotometers for real-time color difference detection and adjustment.

Model Comparison:

Model Type | Core Features | Printing Speed | Color Configuration |

Business Imaging Grade | High-precision graphics, suitable for photo albums and catalogs | 15㎡/hour | CMYK + white ink |

Industrial High-speed | Dual-channel synchronous printing, supports double-sided imaging | 150㎡/hour | CMYK + white ink + varnish |

Wide-format Advertising | 5m ultra-wide format, outdoor weather-resistant inks | 50㎡/hour | CMYK + light cyan + light magenta |

Industry Applications:

Commercial Printing: Corporate brochures, high-end product catalogs requiring Pantone color certification.

Outdoor Advertising: Vehicle wraps, lightbox fabrics, and other applications requiring UV-resistant inks.

Technical Highlights:

Electronic Shaft Synchronization: Controls motion errors of multiple heads within ±0.01mm, ensuring accurate color registration.

White Ink Circulation System: Recovers excess white ink through negative pressure, reducing waste (e.g., Ricoh Ri 1000 series).

| Feature | Multi Pass Printer | Single Pass Printer |

|---|---|---|

| Speed | Slower (depends on scan passes) | Extremely fast (single-pass completion) |

| Precision & Color | Ultra-high resolution, natural gradients | High resolution, but slight color discrepancies may occur |

| Media Compatibility | Broad, supports specialty materials | Limited, mainly standard paper and textiles |

| Cost | Higher equipment and consumable costs | Lower cost, suitable for mass production |

| Application Scenarios | Professional imaging, art, precision industries | Textile printing, packaging, bulk advertising printing |

3. Hybrid Printers

Technical Principles:

Modular Design: The base inkjet unit can be expanded with additional modules like laser engraving, 3D texture printing, or cold foil stamping.

Hybrid Process Engine: Combines processes such as inkjet base printing, laser embossing, and laminating for protection.

Model Comparison:

Model Type | Core Features | Additional Modules | Application Fields |

Packaging Hybrid | Integrates inkjet + die-cutting + inspection | Online inspection camera | Food, pharmaceutical packaging |

Decorative Hybrid | Inkjet + laser engraving/foil stamping | Fiber laser engraving head | Luxury goods, electronics |

Industrial Marking | Inkjet + RFID chip implantation | RFID encoder | Automotive part traceability |

Industry Applications:

Anti-counterfeiting Packaging: Simultaneously prints variable QR codes and laser micro-engraved anti-counterfeit marks on wine boxes.

Smart Labels: Implants temperature-sensing RFID chips during printing for cold chain logistics monitoring.

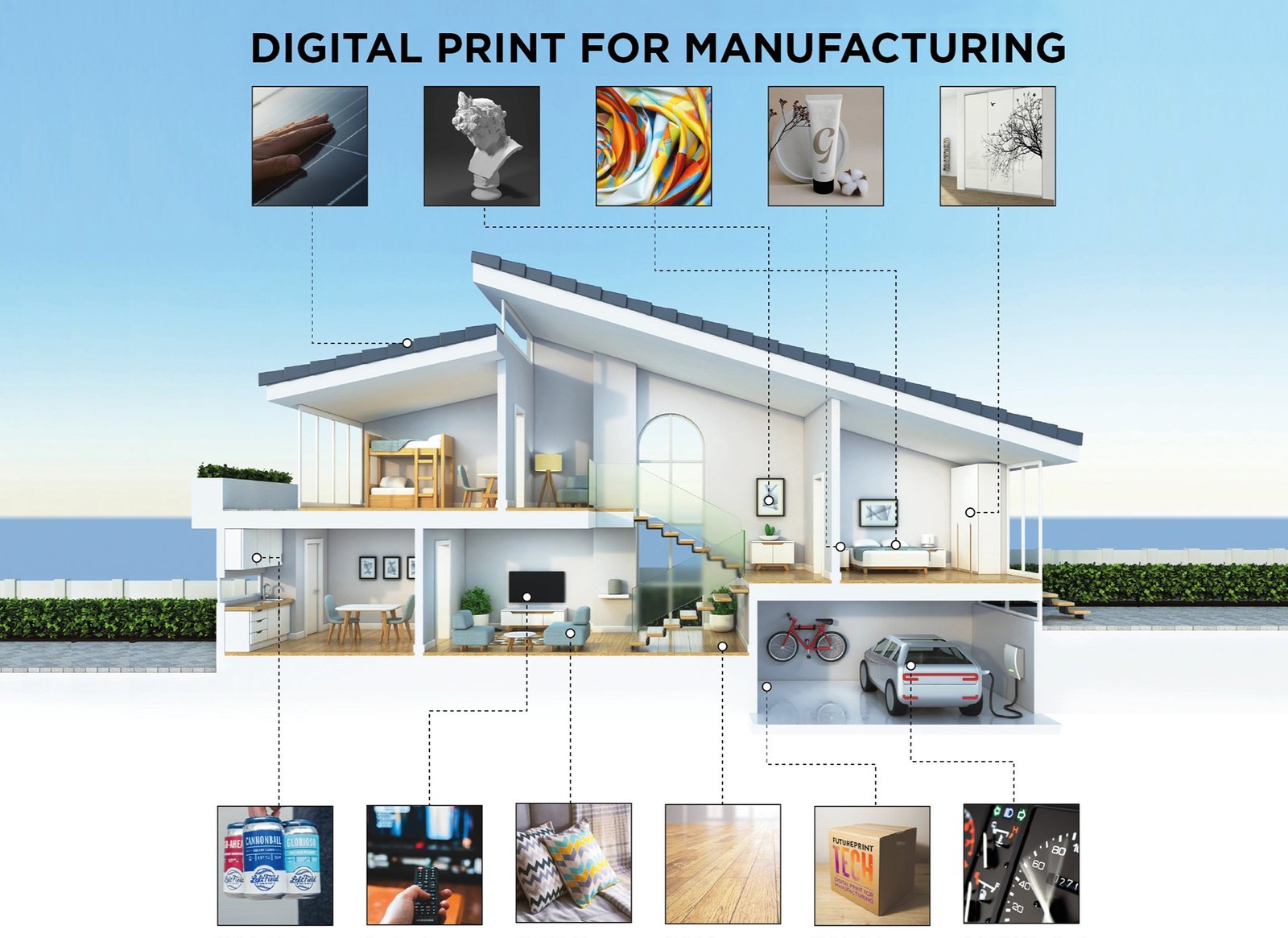

IV. Application Fields of Digital Plate-less Printers

The technical features of digital plate-less printers—such as no need for plate-making, high precision, and compatibility with multiple media—have enabled breakthrough applications across various industries.

1. Packaging Industry

Industry Pain Points:

Traditional Packaging Printing: High plate-making costs, long lead times, and poor cost-effectiveness for small-batch orders.

Inventory Pressure: Requires pre-production of large quantities of standard packaging, leading to high risks of overstocking (especially in the food and cosmetics industries).

Technical Solutions:

Small-batch Customization:

Directly prints variable information (e.g., batch numbers, promotional codes), eliminating the need for repeated plate-making.

Supports “one-cut” printing for irregular boxes and folding cartons (e.g., automatically adapting layouts using 3D model files).

Special Processes:

UV Spot Gloss: Adds a tactile, raised effect to specific areas (e.g., logos), enhancing product appeal.

White Ink Base Layer: Prints a white ink layer on dark corrugated boards before adding colored patterns, solving color deviation issues in traditional printing.

Case Studies:

Food Packaging: An organic snack brand uses digital plate-less printers to produce 5,000–10,000 packaging boxes monthly for different flavors, reducing design iteration cycles from two weeks to one day.

Luxury Packaging: A French perfume brand employs hybrid printers to simultaneously print embossed textures and metallic inks on boxes, reducing per-unit costs by 40% compared to traditional foil stamping.

2. Advertising and Promotional Materials

Industry Pain Points:

Traditional Advertising Printing: Bulk production leads to inventory buildup, failing to meet dynamic needs like pop-up stores or limited-time promotions.

Outdoor Durability: Regular inks fade easily and cannot withstand sun and rain.

Technical Solutions:

Instant Output:

Designers can finalize drafts in the morning and deliver finished products (e.g., exhibition backdrops, roll-up banners) by the afternoon.

Supports “city-targeted advertising,” quickly adjusting content based on regional audience characteristics.

Enhanced Durability:

Uses solvent-based/UV inks with abrasion and UV resistance exceeding ISO Grade 5.

Optional lamination modules provide waterproof and scratch-proof protection.

Case Studies:

Subway Advertising: A sports brand used digital plate-less printers to produce different versions of posters featuring various athletes for 30 city subway stations within a week, reducing costs by 55% compared to traditional batch printing.

Vehicle Advertising: A logistics company adopted wide-format printers to directly print ads on truck bodies, achieving three-year durability and saving 60% over traditional vinyl wrapping.

3. Publishing and Education

Industry Pain Points:

Traditional Publishing: High minimum print runs (typically 5,000 copies or more), with over 30% of unsold books destroyed.

Educational Materials: Standardized textbooks fail to meet differentiated teaching needs.

Technical Solutions:

Print-on-Demand (POD):

Supports printing single copies, enabling a “zero inventory” model through online order platforms.

Automatic binding modules handle finishing processes like glue binding and saddle stitching.

Personalized Teaching Tools:

Customizes exercise book covers and knowledge point labels for different grades/classes.

Prints erasable teaching aids (e.g., whiteboard stickers, experiment record cards).

Case Studies:

Rare Book Reprints: A book publisher uses digital plate-less technology to directly print scanned copies of rare books, achieving five times the profit of traditional printing.

School Customization: A U.S. private school prints annual commemorative booklets with each student’s name and photo on the cover, increasing parent payment conversion rates by 90%.

4. Industrial and Consumer Goods

Industry Pain Points:

Industrial Labeling: Traditional screen printing requires stencils, making it unsuitable for small-batch, multi-model production.

Consumer Goods Homogenization: Lack of personalized designs limits product premium potential.

Technical Solutions:

Direct-to-Object Printing (DTO):

Prints directly on metal, glass, ceramics, etc., with adhesion passing cross-cut tests (ASTM D3359).

Industrial-grade UV inks resist alcohol, acids, and alkalis (compliant with ISO 2813).

Personalized Customization:

C2M (Customer-to-Manufacturer) model: Users design patterns online, and factories print and ship directly (e.g., phone cases, water bottles).

3D Texture Printing: Achieves wood grain or stone textures through multi-layer white and colored ink layering.

Case Studies:

Appliance Panels: A premium refrigerator brand prints marble-like textures directly on stainless steel panels, increasing unit prices by $2,000.

Promotional Gifts: A coffee chain uses digital plate-less printers to produce 20,000 city-exclusive cup sleeves monthly, generating over a million social media impressions.

5. Labels and Tickets

Industry Pain Points:

Traditional Label Printing: Requires mass printing of identical labels, unable to embed dynamic data.

Ticket Security: High anti-counterfeiting requirements, with traditional printing being easily replicated.

Technical Solutions:

Variable Data Printing (VDP):

Generates unique serial numbers, QR codes, or invisible watermarks (e.g., Microtext technology) for each label/ticket.

Direct database integration: Pulls real-time data from ERP systems (e.g., drug traceability codes, logistics numbers).

Enhanced Anti-counterfeiting:

Fluorescent Inks: Display hidden information under UV light.

Scratch-off Layers: Cover variable code areas to prevent pre-reading.

Case Studies:

Pharmaceutical Labels: A pharmaceutical company uses digital plate-less printers to print unique traceability codes on each drug package, improving recall efficiency by 70%.

E-invoices: Supermarket POS systems automatically generate e-invoices with dynamic QR codes, reducing paper consumption by 80%.

V. Future Development Trends

Intelligence and Automation:

AI technology will optimize color management, while IoT (Internet of Things) will enable remote monitoring and control of printing processes.

Expanded Material Compatibility:

Development of inks and printheads compatible with a wider range of specialized media, such as flexible substrates, textiles, and 3D surfaces.

Deepening Green Technologies:

Promotion of zero wastewater discharge processes and improved energy efficiency to meet stricter environmental regulations.

Digital plate-less printers, with their efficiency, flexibility, and eco-friendly features, are reshaping the printing industry. Whether for small and medium-sized enterprises or large manufacturers, this technology offers a pathway to cost reduction, efficiency improvement, and sustainable development goals.

For more details on specific models or industry case studies, feel free to consult us for additional product information and reports.