Why is a Single Pass Printer

a Better Investment Than Traditional Printing Methods?

- 4 3 月, 2025

- FERONIAYANG

- 10:31 上午

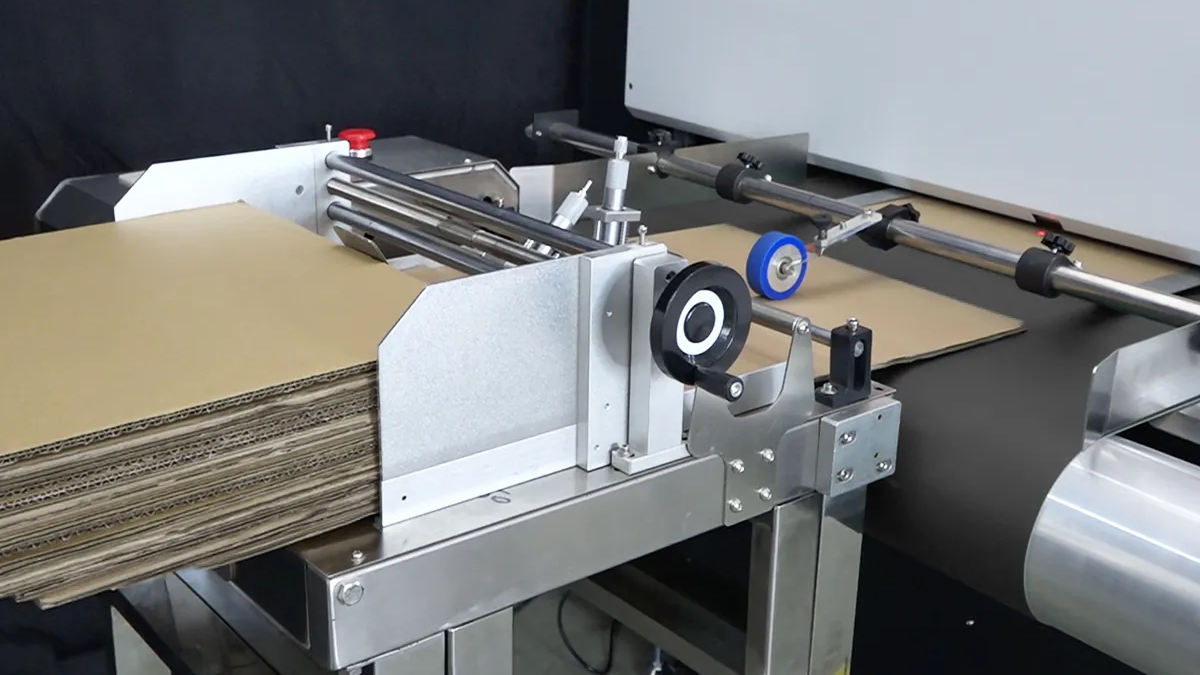

The Single Pass Digital Printer (also known as One-Pass Printer or Carton Printer) has emerged as a transformative force in the packaging and printing industries. As businesses grapple with rising demands for speed, customization, and sustainability, this technology offers a strategic leap over traditional methods like offset, flexography, or screen printing. By eliminating multi-pass workflows and integrating advanced digital controls, single-pass systems achieve unparalleled efficiency while maintaining exceptional quality. Below is a comprehensive analysis of why this innovation represents a superior investment for forward-thinking enterprises.

Catalog

1. Revolutionary Speed: 3X Faster Output with Seamless Integration

Technical Mechanism:

Single-pass printers utilize linear array printheads aligned across the substrate width. Unlike traditional multi-pass systems that require repeated passes for color layering, single-pass technology deposits all ink layers (CMYK + white/varnish) in a single traverse, achieving speeds of 100-300 meters/minute—3-5x faster than rotary screen printers.

Industry Data:

A 2024 study by Smithers Pira revealed that single-pass printers reduce production time by 68% for corrugated packaging compared to analog methods, enabling daily outputs exceeding 50,000 sqm for large-scale facilities.

Operational Advantages:

Zero Drying Delays: UV-LED curing modules instantly dry inks, eliminating bottlenecks caused by conventional drying tunnels.

Continuous Production: Compatible with inline die-cutting and folding machines, enabling end-to-end automated lines.

2. Uncompromised Quality: Precision Meets Consistency

Color Management Breakthroughs:

Closed-Loop Color Control: Integrated spectrophotometers scan every print in real-time, adjusting ink density to maintain ΔE <1.5 across batches—critical for brand compliance.

High-Definition Output: With resolutions up to 1200×1200 DPI and droplet sizes as small as 3 picoliters, single-pass printers reproduce gradients and fine text surpassing traditional 175 LPI offset quality.

Material Versatility:

Universal Media Handling: From 0.1mm PET films to 10mm corrugated boards, adaptive vacuum belts and height sensors ensure stable printing without deformation.

White Ink Optimization: Layered white underprinting on dark substrates (e.g., black kraft paper) achieves 90% opacity, resolving traditional screen printing’s uneven coverage issues.

3. Agile Production: From Mass Customization to On-Demand Manufacturing

Breaking Traditional Constraints:

Zero Plate Costs: Traditional offset requires 500−500−2000 per plate setup, making short runs (<5000 units) economically unviable. Single-pass systems operate plate-free, enabling 1-unit batches at consistent per-unit costs.

Dynamic Content Printing: Variable data capabilities embed unique QR codes, serial numbers, or regionalized designs without stopping production—ideal for anti-counterfeiting or personalized packaging.

Market Responsiveness:

Fast Prototyping: Designers can test 10 packaging variants in a day (vs. 1 variant/week with analog methods), accelerating time-to-market by 75%.

Sustainability Alignment: On-demand production reduces inventory waste; a 2023 McKinsey report found single-pass adopters cut packaging stockpiles by 40%, aligning with ESG goals.

4. Cost Efficiency: Lower TCO with Higher ROI

Direct Savings Analysis:

| Cost Factor | Traditional Offset | Single-Pass Printer | Reduction |

|---|---|---|---|

| Setup (per job) | 800−800−1,500 | $0 (digital files) | 100% |

| Labor (hourly) | $45 (skilled operator) | $15 (automated) | 67% |

| Energy Consumption | 15 kWh/m² | 5 kWh/m² | 66% |

| Waste Rate | 5%-10% | <1% | 80%-90% |

Indirect Financial Benefits:

Space Optimization: Compact footprint vs. 20m²+ for offset lines, reducing facility costs.

Scalability: Modular designs allow adding printheads for capacity boosts without full system replacement.

5. Sustainability: Eco-Conscious Printing Redefined

Green Technology Innovations:

UV-LED Inks: VOC-free formulations comply with EU REACH/EPA standards, reducing hazardous emissions by 95%.

Energy Recovery: Heat from UV lamps reused for substrate pre-heating, cutting net energy use by 30%.

Circular Economy: Biodegradable water-based inks enable recyclable packaging streams.

Certification Edge:

Brands like IKEA and Unilever now mandate suppliers to use digital printing for Cradle-to-Cradle certification compliance—a market access advantage for single-pass adopters.

6. Future-Proofing: Smart Integration & Industry 4.0 Readiness

IoT & AI Integration:

Predictive Maintenance: Sensors monitor printhead health, predicting failures 48+ hours in advance.

Cloud-Based Workflow: Adobe PDF/VPS files auto-optimized via AI for color consistency across global facilities.

Blockchain Applications:

Pairing single-pass printers with blockchain platforms enables end-to-end traceability—each package printed with encrypted QR codes for supply chain transparency.

Conclusion: Strategic Investment for Competitive Dominance

The single-pass digital printer transcends being mere equipment—it embodies a paradigm shift toward agile, sustainable, and intelligent manufacturing. By slashing production timelines, enabling hyper-customization, and aligning with global decarbonization goals, this technology delivers ROI within 12-18 months for most converters.

For businesses poised to lead in e-commerce, luxury packaging, or regulated industries (pharma/logistics), adopting single-pass systems isn’t optional—it’s imperative. As the gap between analog and digital widens, early adopters will seize market share while laggards face obsolescence.

For more details on specific models or industry case studies, feel free to consult us for additional product information and reports.