Digital Printing Overview

Digital printing is a method of printing from a digital-based image directly to a variety of media.It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and/or high-volume laser or inkjet printers.

Digital printing has a higher cost per page than more traditional offset printing methods, but this price is usually offset by avoiding the cost of all the technical steps required to make printing plates. It also allows for on-demand printing, short turnaround time, and even a modification of the image (variable data) used for each impression.

Three Different Imaging Techniques

Multi-Pass

Multi-pass printing is when the print heads or printed object move axially in steps down the part, like a flatbed printer.

Single Pass

Single pass involves using an array of print heads to print the full image length with a single revolution of the printed object.

Helical Printing

Helical printing is a hybrid method between the single-pass and multi-pass approaches. Image data is mapped to allow continuous imaging in a helical pattern with a limited number of print heads.

Single Pass Printer Overview

The Single Pass Printer

(also known as One Pass Printer) is a revolutionary digital printing solution designed for high-speed, precision, and energy-efficient industrial applications. Utilizing advanced Single Pass scanning technology, it enables full-image printing in a single scan, eliminating the need for multiple passes and significantly boosting productivity while maintaining exceptional print quality. Ideal for industries requiring rapid, large-scale printing with minimal downtime.

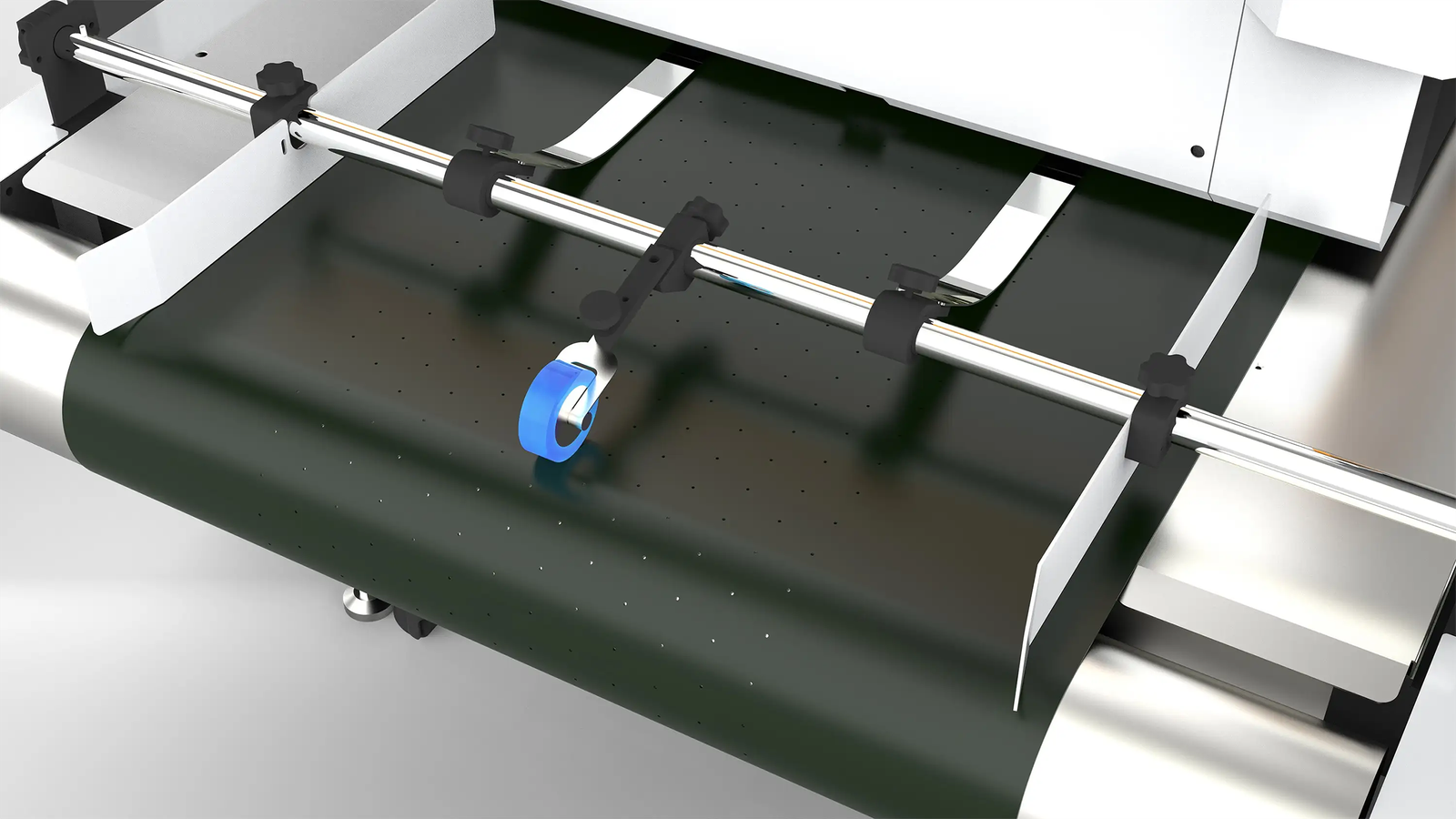

Working Principle

In a single-pass printer, multiple printheads are arranged across the width of the substrate. As the substrate moves continuously through the printer, all printheads operate simultaneously, depositing ink onto the substrate in a single pass. This method eliminates the need for multiple passes, resulting in faster printing speeds and improved efficiency.

Single Pass Products

QUALITY ASSURANCE IS TRUSTWORTHY

Onepass EAS-C

EAS-C1800

- Print Head: A4

- No.s of Print Head: 5

- Maximum Overpass Paper: 1800mm

- Print Wide Width: 108cm

EAS-C1800S

- Print Head: A3

- No.s of Print Head: 5

- Maximum Overpass Paper: 1800mm

- Print Wide Width: 150cm

Onepass EAS-A

EAS-A360

- Print Head: A3

- No.s of Print Head: 1

- Maximum Overpass Paper: 350mm

- Print Wide Width: 30cm

EAS-A680

- Print Head: A3

- No.s of Print Head: 2

- Maximum Overpass Paper: 650mm

- Print Wide Width: 60cm

Onepass EAS-V

EAS-V1300

- Print Head: A4

- No.s of Print Head: 3

- Maximum Overpass Paper: 1300mm

- Print Wide Width: 65cm

EAS-V1300S

- Print Head: A3

- No.s of Print Head: 2

- Maximum Overpass Paper: 1300mm

- Print Wide Width: 60cm

Onepass EAS-EP

MFT-GLS350GS

- Print Head: I3200

- No.s of Print Head: 24

- Maximum Overpass Paper: 1800mm

- Print Wide Width: 80cm

MFT-AMG S600

- Print Head: I3200

- No.s of Print Head: 66

- Maximum Overpass Paper: 2500mm

- Print Wide Width: 216cm

Onepass EAS-U

EAS-U360

- Print Head: I3200

- No.s of Print Head: 10

- Maximum Overpass Paper: 300mm

- Print Wide Width: 67cm

EAS-U680

- Print Head: S3200

- No.s of Print Head: 10

- Maximum Overpass Paper: 650mm

- Print Wide Width: 240cm

Onepass EAS-R

EAS-R350

- Print Head: S3200

- No.s of Print Head: 10

- Maximum Overpass Paper: 300mm

- Print Wide Width: 240cm

EAS-R680

- Print Head: S3200

- No.s of Print Head: 25

- Maximum Overpass Paper: 650mm

- Print Wide Width: 600cm

Key Features & Technical Specifications

High-Speed Performance

Achieves speeds up to 75–80 meters per minute, with hourly output reaching 4,800 meters, rivaling traditional rotary screen printing efficiency. Making them ideal for high-volume production environments.

High Precision

These printers offer high-resolution printing capabilities, fixed print heads ensure stable inkjet control, reducing motion-related errors and enhancing precision (up to 2,400 DPI).Ensuring sharp and clear images and text.

Multi-Process Compatibility

Supports hybrid printing modes, including digital + rotary screen overprinting, 12-color metallic/foam/gradient effects, and online sizing integration, enabling complex, multi-layered designs in a single run.

Energy Efficiency & Sustainability

Reduces energy consumption by 30–40% compared to multi-pass printers, aligning with eco-friendly production goals.Lowers total nitrogen emissions and minimizes post-processing waste through advanced ink management systems.

Industrial-Grade Durability

Robust mechanical design and intelligent control systems ensure 24/7 continuous operation.

Versatile Material Compatibility

They can print on a wide range of substrates, including paper, cardboard, plastics, metals, glass, ceramics, and wood, accommodating diverse printing needs.Ideal for printing on labels, packaging, garments, industrial parts, and decorative items.

Digital Printing Printhead

Features: HP printheads are widely used in digital printing equipment and industrial inkjet coding devices. Commonly used A4/A3 printheads offer high cost-effectiveness, with an A4 printhead lifespan of 3-6 months and an A3 printhead lifespan of 6-12 months. The printing resolution ranges from 600 to 1200 DPI.

Representative Products:

HP Officejet Pro Series Printheads: Designed for business inkjet printers, these printheads support high-precision printing and fast task processing.

Applications: Packaging and label printing, wide-format printing, office and business printing.

Features: A global leader in piezoelectric printheads, Epson’s products range from office printing to industrial applications, known for high precision and stability.

Representative Products:

i3200/4720 Series: Used in high-speed digital textile printers and UV flatbed printers, supporting high-precision white ink transfer and advertising printing.

Applications: Textile printing, advertising signage, label printing.

Features: Specializes in industrial-grade printheads, known for high speed, durability, and low maintenance costs.

Representative Products:

KJ4B Series (e.g., KJ4B-QA, KJ4B-YH): Suitable for digital textile printers and inkjet coders, supporting high-speed water-based ink printing.

Applications: Textile printing, packaging printing, industrial marking.

Features: A leader in industrial printhead technology, particularly skilled in UV ink and high-precision printing.

Representative Products:

Ricoh G5/GH2220 Printheads: Used in high-speed UV flatbed printers and digital belt printing equipment, supporting multi-material printing (e.g., phone cases, metal, glass).

Applications: Industrial part marking, 3D decorative printing, textile printing.

Features: Develops mid-to-low-end piezoelectric printheads based on Xaar technology, offering cost-effective solutions.

Applications: Advertising signage, textile printing.

Features: Focuses on the textile sector, offering affordable printheads with limited frequency and lifespan.

Applications: Mid-to-low-end digital textile printing.

Industrial printheads for high-precision label and packaging printing, often paired with LanYu inks.

Some printheads are used in textile and UV printing equipment.

Industrial printheads are applied in specific fields (e.g., electronic component marking).

Digital Printing Inks

1. Water-Based Inks (Aqueous Inks):

Characteristics: Solvent-based on water, environmentally friendly and non-toxic.

Applications: Suitable for highly absorbent media such as paper and synthetic paper, commonly used in office and home printing.

2. Solvent Inks:

Characteristics: Based on organic solvents, offering strong adhesion and weather resistance.

Applications: Suitable for non-absorbent media like vinyl and PVC, widely used in outdoor advertising and signage production.

3. UV-Curable Inks:

Characteristics: Contain photoinitiators that cure under ultraviolet light, drying quickly and providing strong weather resistance.

Applications: Suitable for various materials, including paper, plastic, and metal, widely used in packaging, labeling, and decorative printing.

4. Latex Inks:

Characteristics: Utilize a water-based formulation with added latex particles, offering quick curing, low volatility, and environmental friendliness.

Applications: Suitable for printing on various media, including paper, vinyl, and fabric, with a wide range of applications.

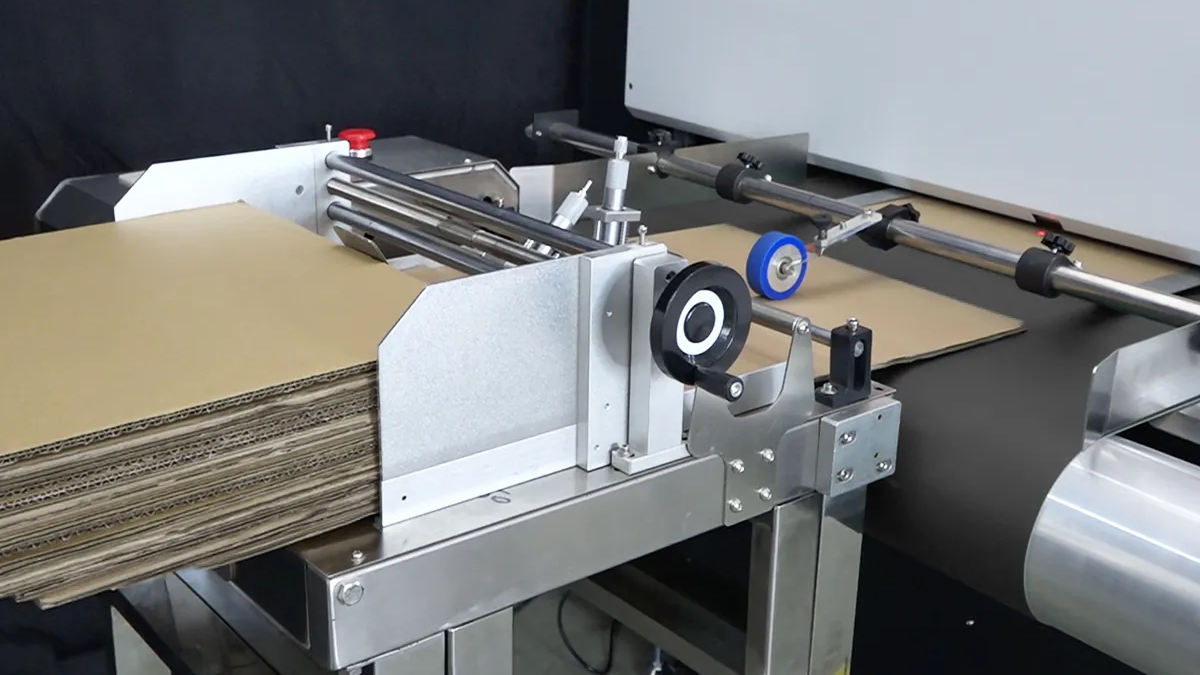

Feeding Methods

| Feeding Method | Efficiency | Precision | Cost | Application Scenarios |

|---|---|---|---|---|

| Manual Feeding | Low | Human-dependent | Low | Small batches, special materials |

| Belt-Driven Feeding | Medium | Moderate | Medium | Small to medium-scale continuous production |

| Servo-Driven Feeding | High | Very High | High | Large-scale, high-precision industrial applications |

Suitable feeding methods can be selected based on production needs, budget, and material characteristics.

Daily Maintenance

Head streaking and clogging are common issues in digital printing, often influenced by factors such as the operating environment, printer maintenance, print material quality, and operator skill level.

Factors Leading to Head Streaking and Clogging:

Operating Environment: Dust, temperature, and humidity can affect head performance, especially without proper protective measures.

Print Materials: Using low-quality inks or materials can cause clogs or streaking around the head.

Insufficient Maintenance: Lack of regular cleaning and upkeep.

Operational Errors: Incorrect actions, such as frequent starts and stops or improper ink changes, leading to streaking or clogs.

While these issues can occur, implementing appropriate preventive measures and maintenance practices can reduce their frequency.

1. Regular Head Cleaning:

Automatic Cleaning: Most digital printers have an automatic cleaning function that periodically cleans the head to prevent ink drying and clogs.

Manual Cleaning: If automatic cleaning doesn’t resolve the issue, use specialized cleaning solutions and lint-free cloths or cotton swabs to gently wipe the head surface, removing residual ink.

2. Maintain a Clean Operating Environment:

Temperature and Humidity Control: Ensure the printer operates in an environment with suitable temperature and humidity to prevent head issues.

Dust Prevention: Regularly clean the printer’s surroundings to minimize dust and debris accumulation, preventing head clogs.

3. Use Quality Inks:

Ink Selection: Use reliable, compatible inks to prevent clogs and damage.

Ink Replacement: When changing inks, empty the old ink and clean the lines with a cleaning solution to ensure smooth flow of the new ink.

4. Regular Inspection and Maintenance:

Head Status Check: Regularly print test patterns to check head performance and promptly address any clogs or uneven printing.

Equipment Upkeep: Periodically clean internal components like rails and belts to ensure proper operation.

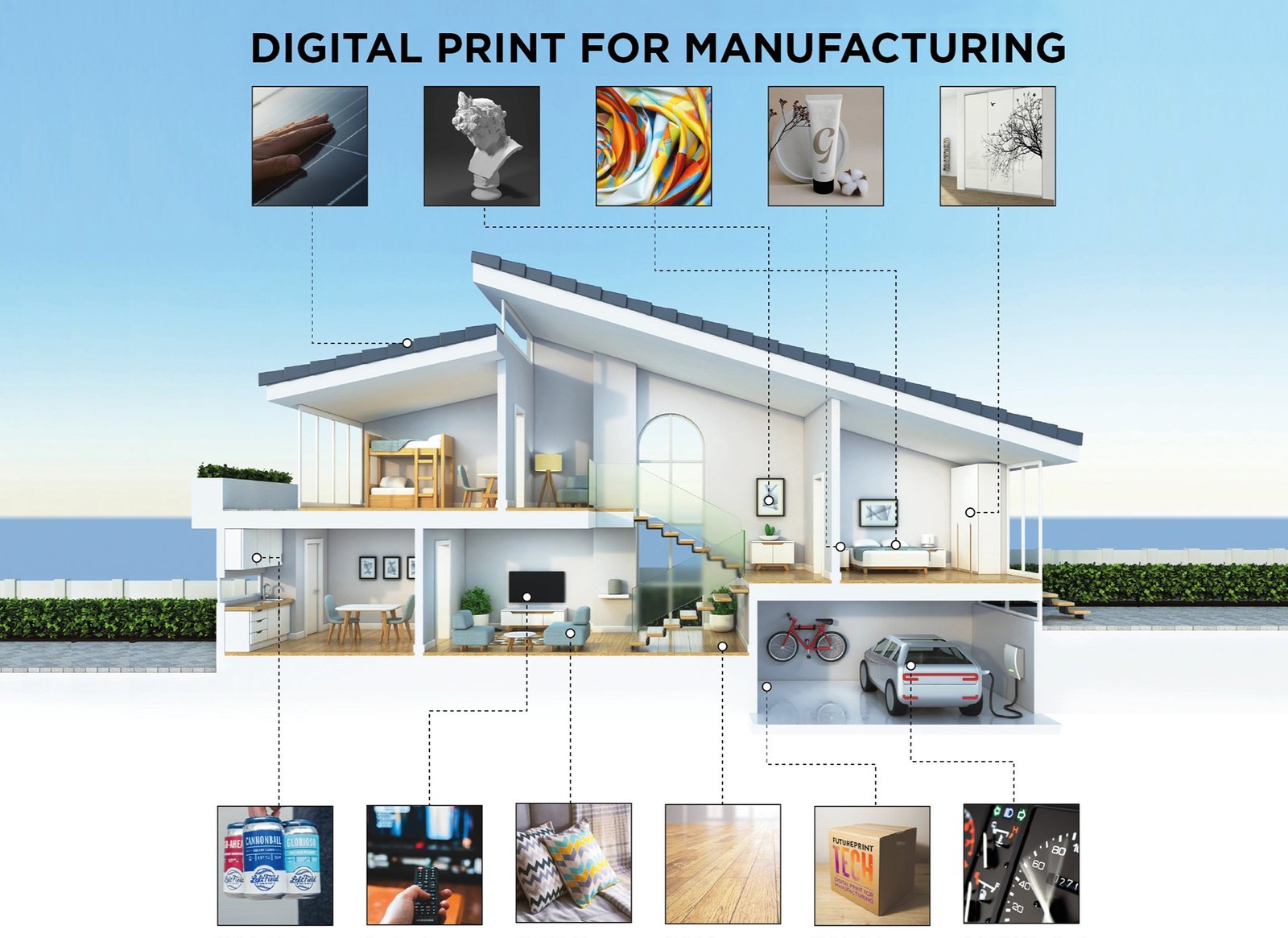

Applications & Industries

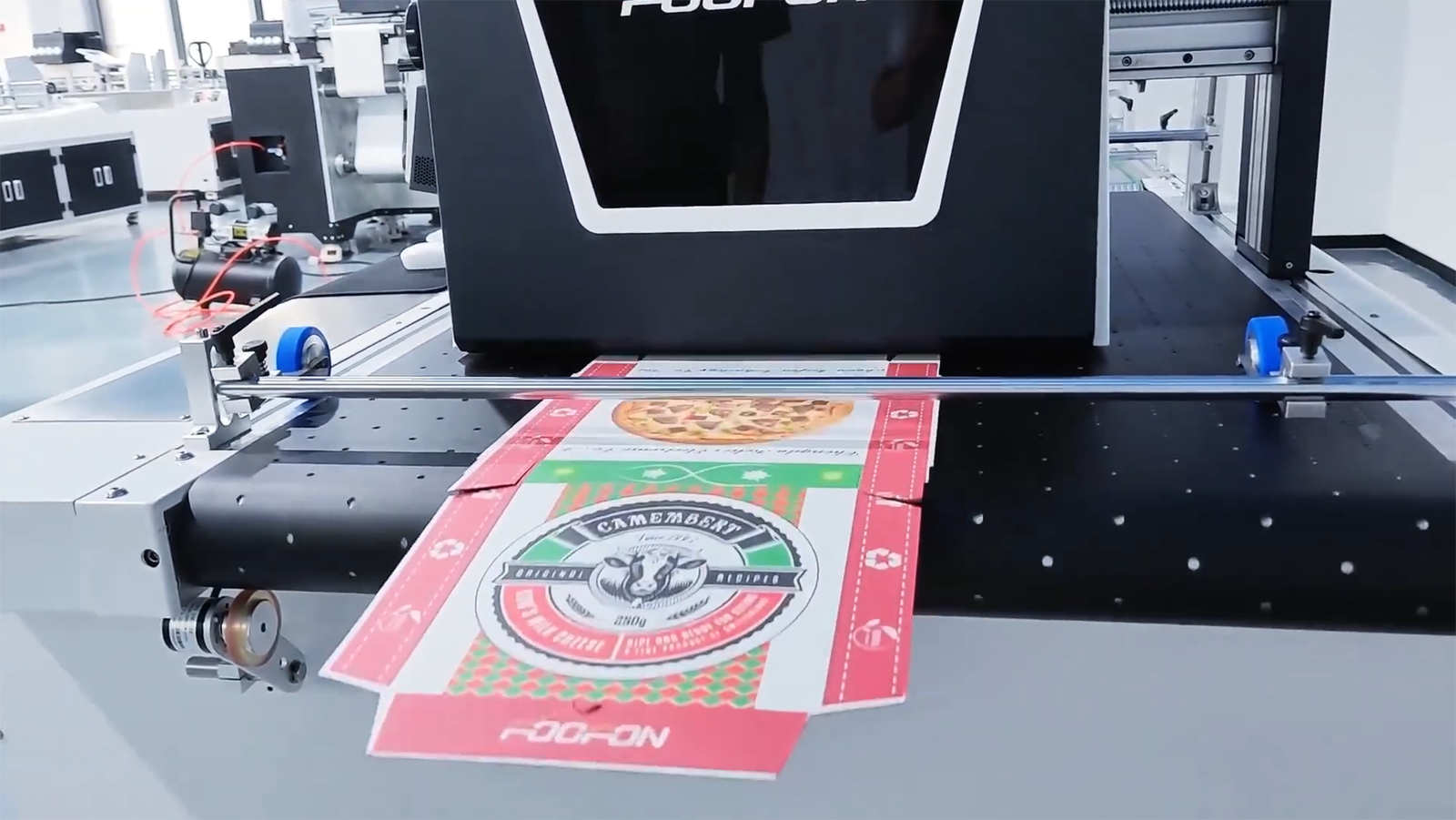

Packaging

In the packaging industry, Single Pass Printers are transforming the way labels, flexible packaging, and point-of-purchase (POP) displays are produced. These printers excel in printing high-resolution graphics, barcodes, and variable data on materials such as paper, corrugated boxes, and metallic foils. Their ability to handle high-speed production without compromising print quality makes them ideal for industries like food and beverage, pharmaceuticals, and consumer goods. For example, they can print intricate designs on snack bags, beverage labels, or cosmetic packaging with exceptional clarity and color accuracy. Moreover, Single Pass Printers support the growing trend of short-run and customized packaging, allowing brands to create limited-edition designs or region-specific packaging with minimal setup time.

Customized Merchandise

Single Pass Printers are widely used to create customized accessories such as phone cases, cosmetic packaging, and gaming products. Their ability to print high-quality, full-color designs on a variety of materials—including plastics, metals, and ceramics—makes them ideal for producing unique, eye-catching items. The speed and efficiency of Single Pass technology also make it cost-effective for small-batch production, allowing businesses to cater to niche markets without incurring high costs. Furthermore, the durability of the prints ensures that the customized products maintain their appearance over time, enhancing customer satisfaction and brand loyalty.

Textile & Apparel

Single Pass Printers have revolutionized the textile and apparel industry by enabling high-speed, high-quality digital printing on a wide range of fabrics, including cotton, polyester, silk, and blends. These printers are ideal for producing vibrant, fade-resistant designs on garments, home textiles (such as curtains, bed linens, and upholstery), and fashion accessories. Unlike traditional screen printing, Single Pass technology eliminates the need for multiple passes, significantly reducing production time and costs. This makes it perfect for both mass production and small-batch customization, catering to the growing demand for personalized and on-demand fashion.

Industrial Manufacturing

Single Pass Printers are increasingly being adopted in industrial manufacturing for applications such as durable part labeling, equipment tags, and promotional items. These printers can handle a variety of substrates, including metals, plastics, and composites, making them versatile tools for industries like automotive, electronics, and aerospace. For instance, they can print serial numbers, QR codes, or safety warnings directly onto industrial components, ensuring durability and legibility even in harsh environments. By enabling on-demand printing and reducing the need for pre-printed labels, these printers help manufacturers streamline operations, cut costs, and improve traceability.

Why Choose Single Pass Technology?

Cost-Effective

Print Quality

Variable Data Printing

Technical Support & Services

Offer operation manual and videos

Proactively get your feedback

One-year warranty for core components

Engineer answer

Solve your problem

Get Started Today!

Explore our groundbreaking solutions Find the one that works best for you.

Ready for growth? Get a personalized quote for our printing solutions today and start transforming your business vision into reality.

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!